Premium Plastic Components Solutions

Discover our comprehensive range of precision-molded plastic components, engineered with advanced manufacturing technology to meet exacting specifications across all industries

Commutator Components

High-precision plastic commutator segments and housings for electric motors, engineered for superior electrical insulation and thermal resistance

Grinding Wheel Substrates

Durable plastic base substrates for grinding wheels, providing excellent dimensional stability and vibration dampening for precision grinding operations

Automotive Components

Precision-molded automotive plastic parts including interior trim, under-hood components, and functional elements engineered for automotive standards

Insulation Sleeves

High-performance plastic insulation sleeves for electrical applications, offering superior dielectric strength and temperature resistance

Welding Clamps

Heat-resistant plastic components for welding clamps and electrode holders, designed to withstand high temperatures and electrical stress

Cookware Handles

Ergonomic heat-resistant plastic handles for cookware, featuring superior grip design and thermal insulation for safe kitchen operations

Precision Housings

Ultra-precise plastic housings and enclosures for electronic devices and instruments, manufactured to tight tolerances with excellent surface finish

Medical Components

Biocompatible plastic components for medical devices and equipment, manufactured under strict quality controls to meet healthcare

Industrial Fasteners

High-strength plastic fasteners and clips for industrial applications, offering corrosion resistance and reliable mechanical properties

Need Custom Plastic Manufacturing Solutions?

Our engineering team specializes in creating precision plastic components tailored to your exact specifications, material requirements, and quality standards across all industries.

Phenolic Molding Compound Technical Specifications

Premium grade phenolic compounds with superior performance characteristics for demanding industrial applications

Performance Indicators

| Property | Test Method | Unit | Typical Value |

|---|---|---|---|

| Tensile Strength | ASTM D638 | MPa | 45-65 |

| Flexural Strength | ASTM D790 | MPa | 80-120 |

| Impact Strength | ASTM D256 | J/m | 15-25 |

| Heat Deflection Temperature | ASTM D648 | °C | 150-180 |

| Density | ASTM D792 | g/cm³ | 1.35-1.45 |

| Water Absorption | ASTM D570 | % | 0.1-0.3 |

| Dielectric Strength | ASTM D149 | kV/mm | 12-18 |

| Volume Resistivity | ASTM D257 | Ω·cm | 10¹²-10¹⁴ |

Industry Applications

| Industry Sector | Applications | Key Benefits | Market Share |

|---|---|---|---|

|

Automotive

|

Brake pads, clutch facings, electrical components | Heat resistance, friction stability | 35% |

|

Electronics

|

Circuit breakers, switches, insulators | Electrical insulation, arc resistance | 28% |

|

Aerospace

|

Interior panels, structural components | Lightweight, fire resistance | 15% |

|

Construction

|

Adhesives, laminates, coatings | Weather resistance, durability | 12% |

|

Industrial Equipment

|

Pump housings, valve components | Chemical resistance, dimensional stability | 10% |

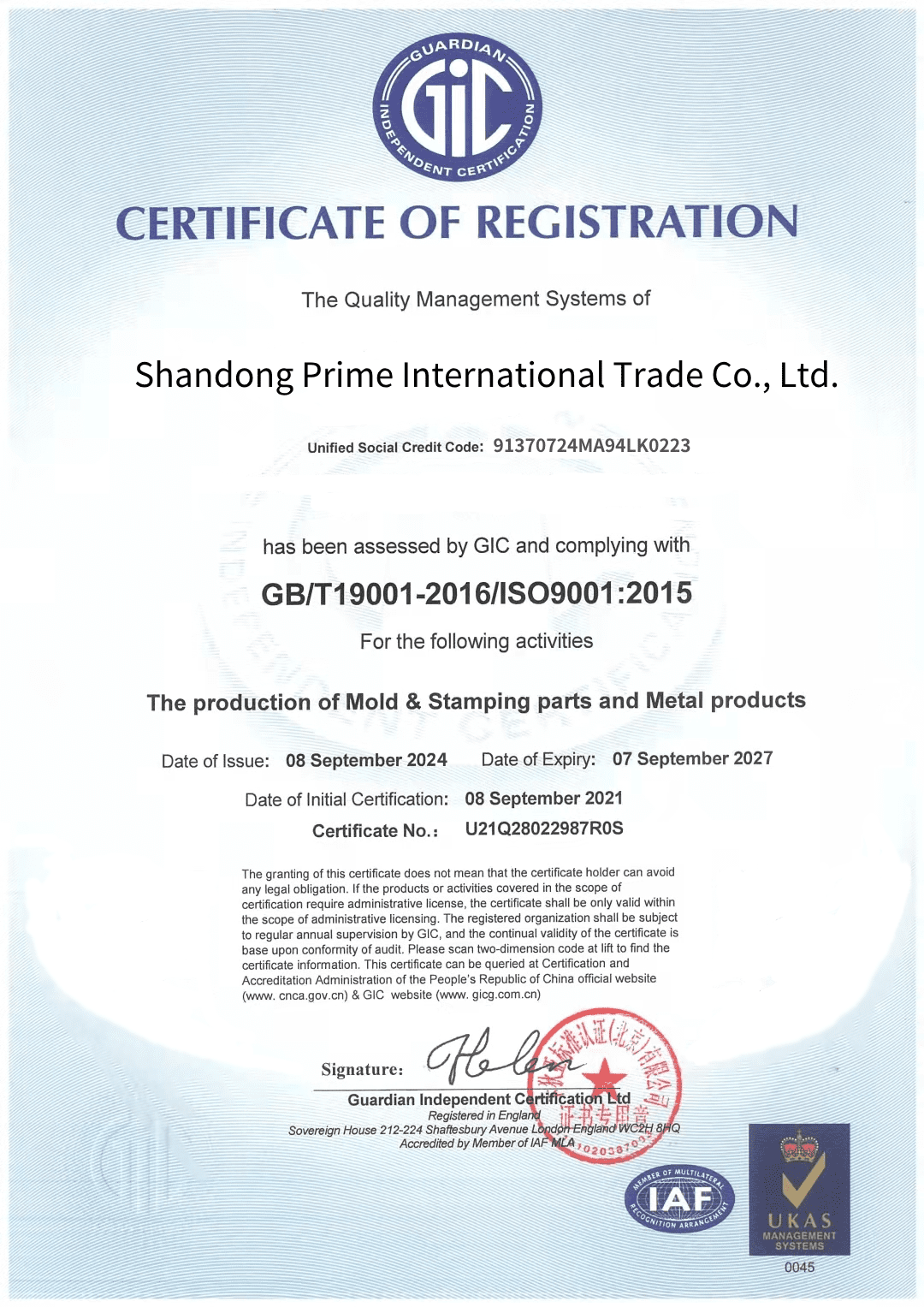

ISO Certified Quality

All compounds meet international quality standards

Custom Formulations

Tailored properties for specific applications

Global Supply

Reliable delivery to 50+ countries worldwide

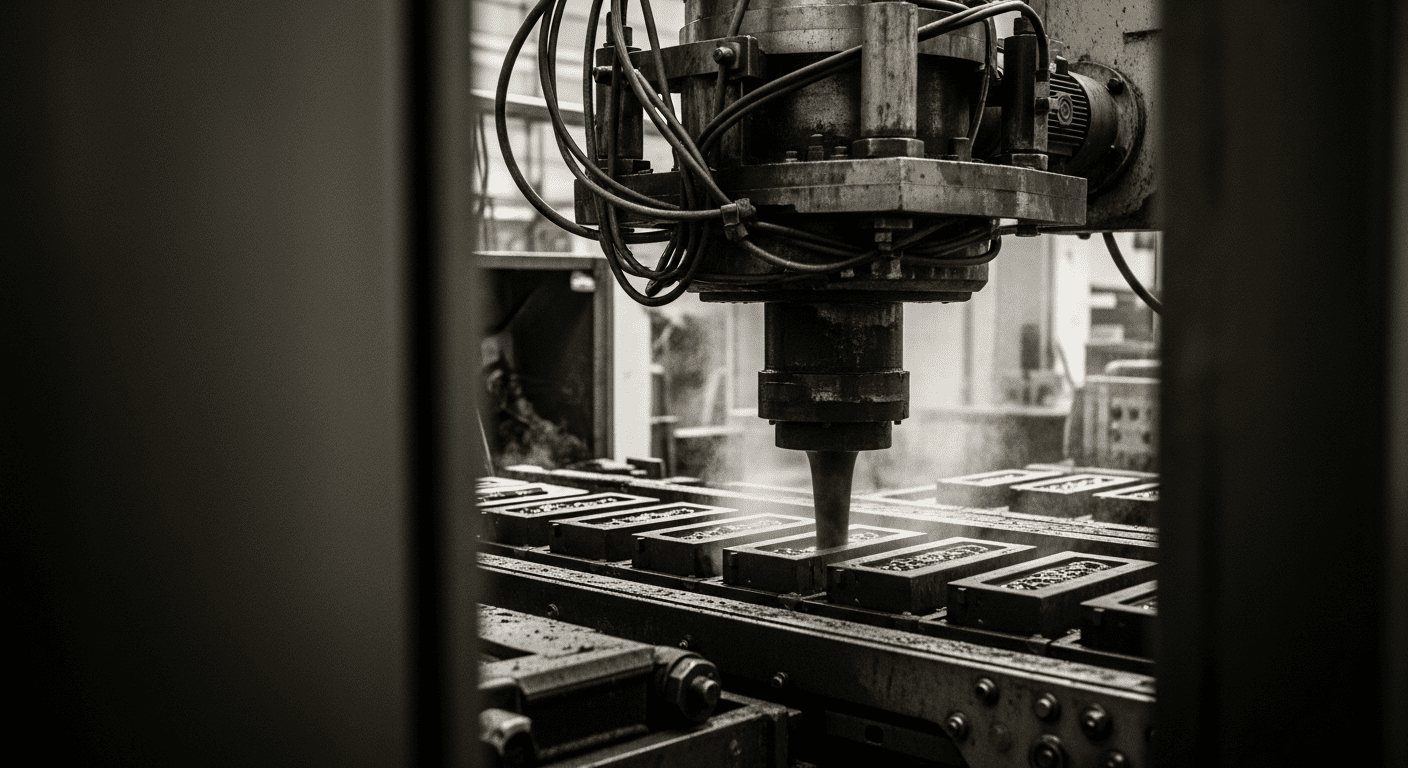

PFM Plastic Parts Manufacturing Process

From material formulation to final delivery - experience our advanced PFM plastic parts production with precision engineering and quality assurance at every stage

Raw Material Formulation

Premium PFM resins, reinforcing fillers, and specialized additives are precisely blended according to custom formulations. Our material engineers optimize each compound for specific thermal, mechanical, and electrical properties.

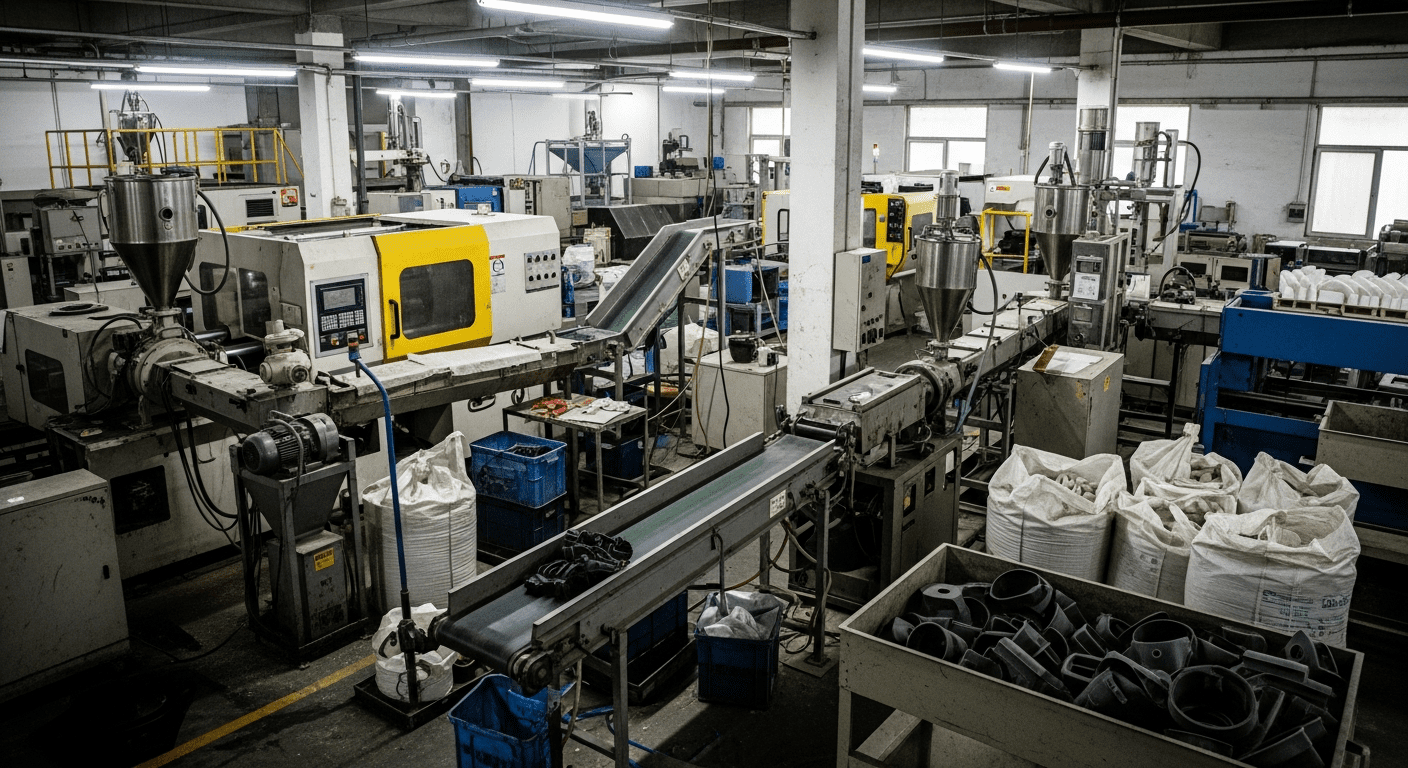

Mixing & Compounding

High-intensity mixers and twin-screw extruders ensure uniform distribution of all components. Temperature-controlled processing maintains optimal resin properties while achieving consistent compound characteristics throughout each batch.

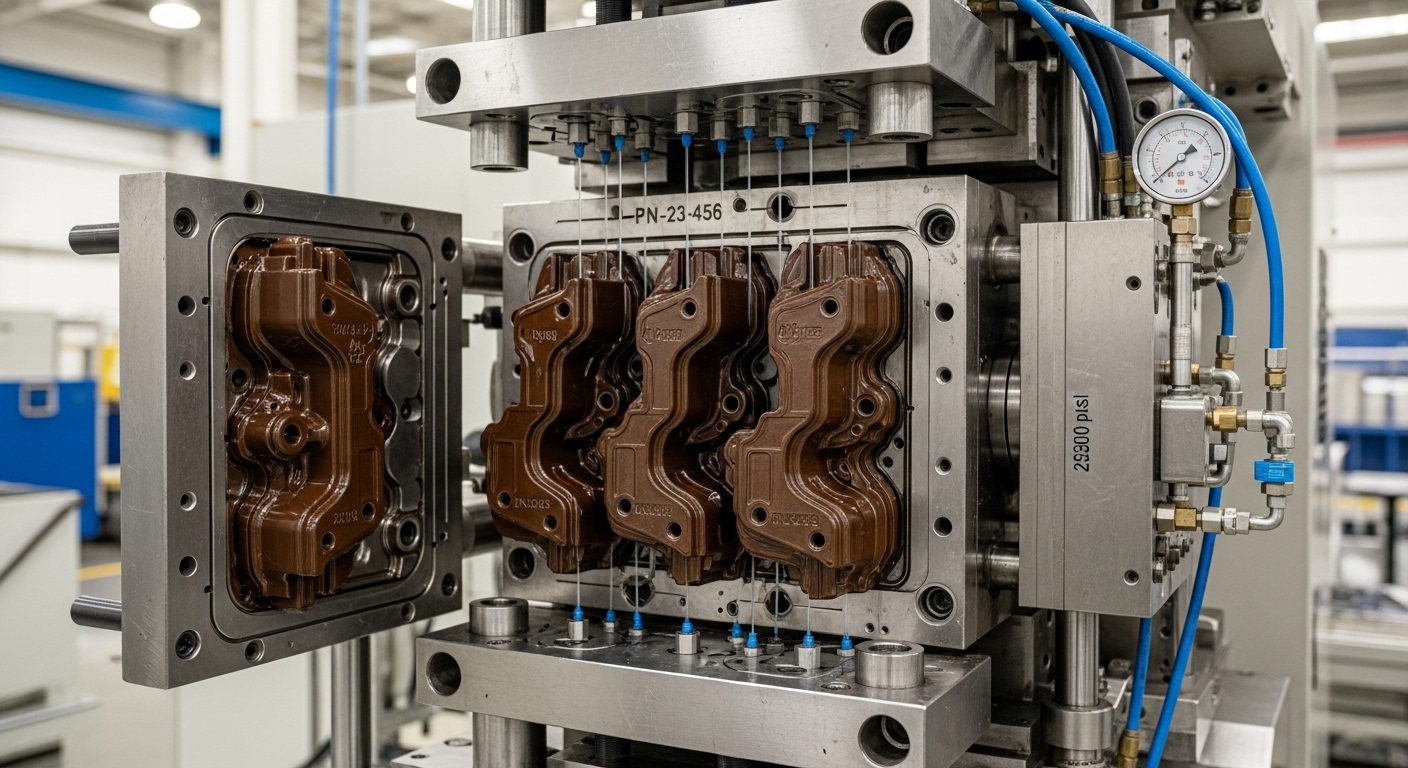

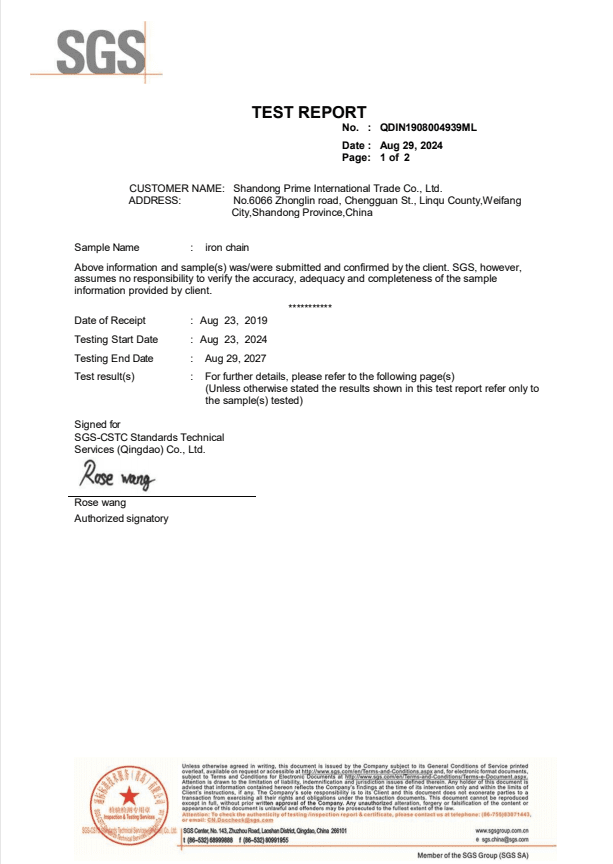

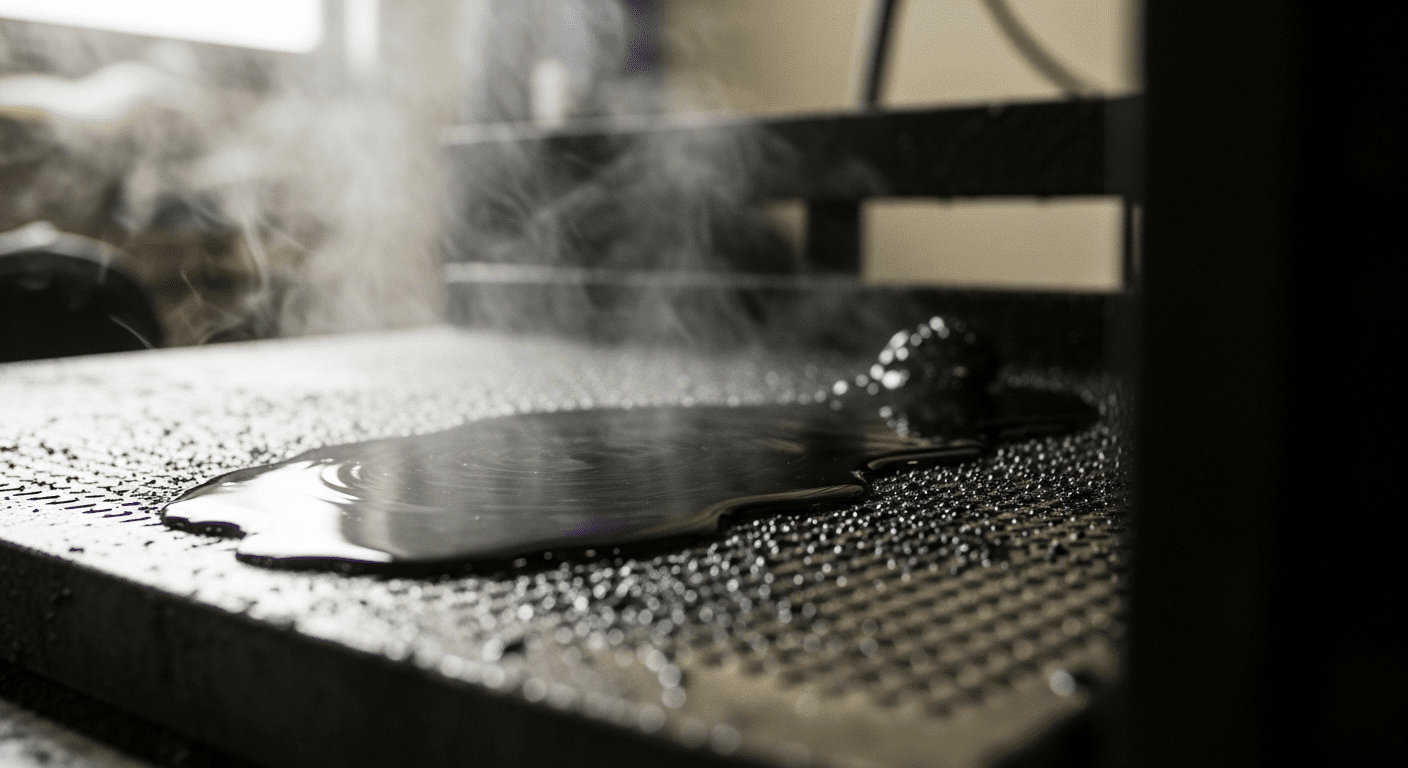

Molding & Curing

10 precision molding presses with automated temperature and pressure controls ensure consistent part formation. Optimized curing cycles develop full cross-linking for maximum strength, heat resistance, and dimensional stability.

Cooling & Precision Finishing

Controlled cooling chambers stabilize PFM plastic parts and relieve internal stresses. Advanced CNC machining and precision finishing operations achieve tight tolerances, smooth surfaces, and exact specifications for custom plastic components.

Quality Testing & Certification

Comprehensive testing includes thermal analysis, electrical properties, mechanical strength, and dimensional verification. ISO-certified quality systems provide detailed test reports and material certifications for critical applications.

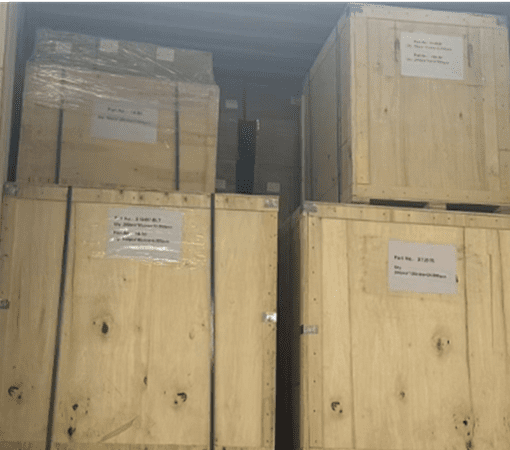

Packaging & Global Shipping

Professional packaging protects PFM plastic parts during international transport. Custom labeling, material safety documentation, and optimized logistics ensure safe delivery to North America, Europe, Middle East, and Australia.

Ready to Experience Our PFM Plastic Manufacturing Excellence?

Start your custom PFM plastic parts project today. Our material engineers will provide comprehensive formulation analysis and detailed specifications within 24 hours.

Phenolic Molding Compounds for Critical Applications

From automotive to aerospace, our premium phenolic molding compounds deliver exceptional thermal resistance, dimensional stability, and mechanical strength for the world's most demanding applications.

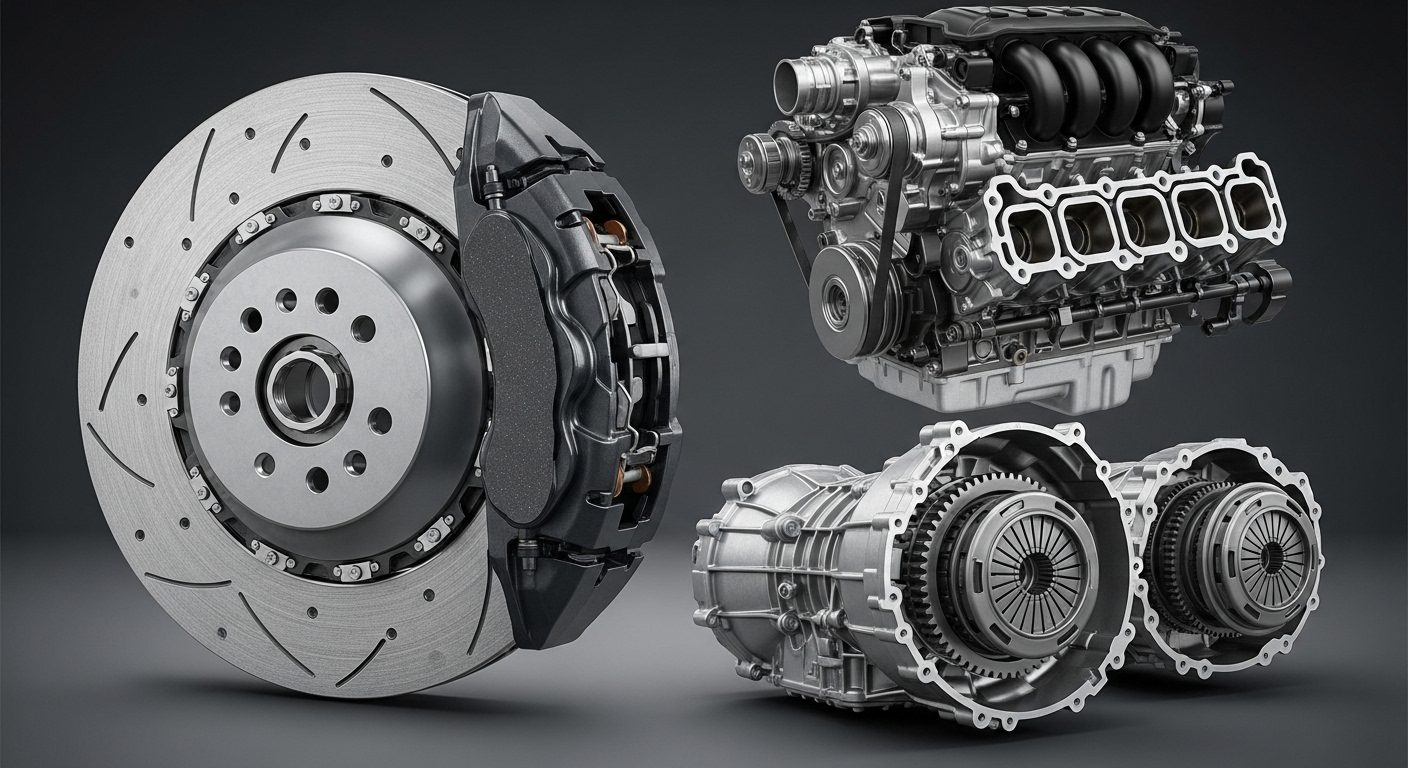

Automotive Industry

High-temperature phenolic compounds for brake components, engine parts, and transmission systems. Superior heat resistance and dimensional stability under extreme automotive conditions.

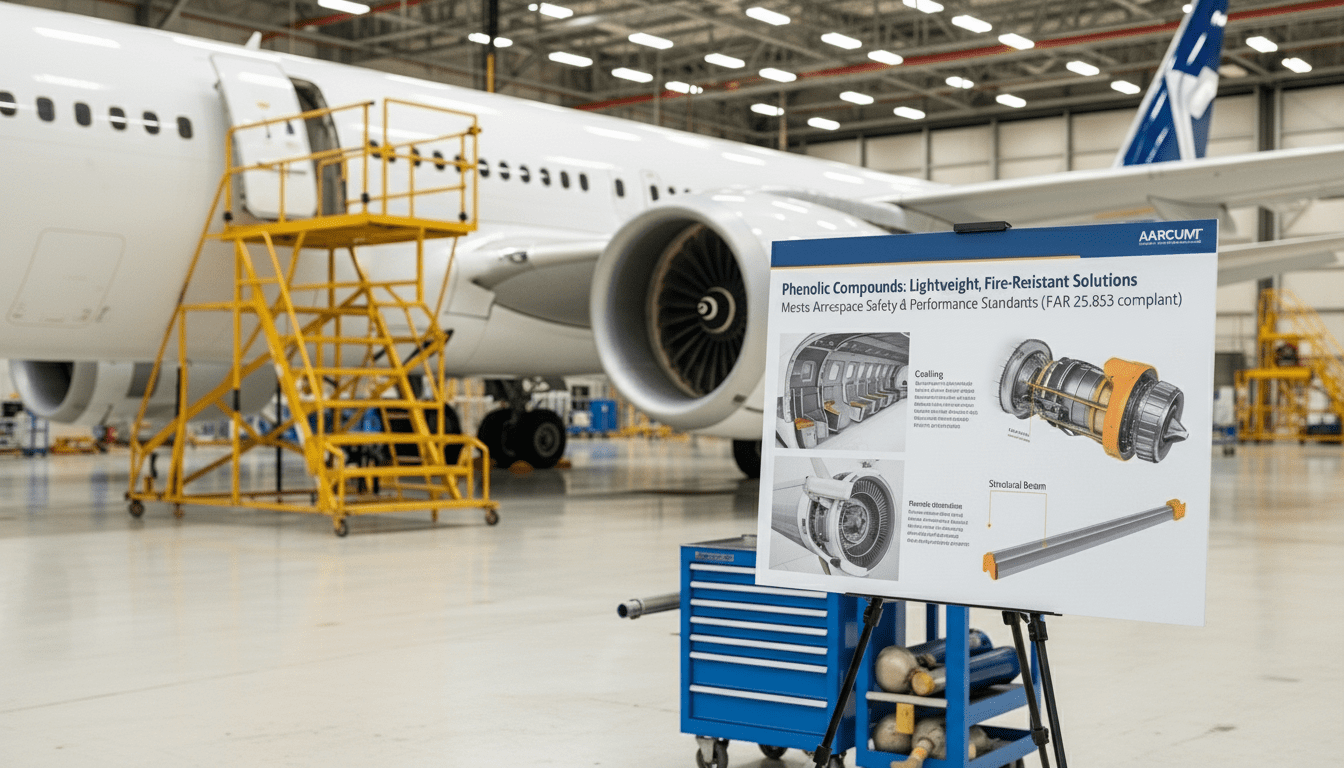

Aerospace Industry

Lightweight, fire-resistant phenolic compounds for aircraft interiors, engine components, and structural applications. Meeting stringent aerospace safety and performance standards.

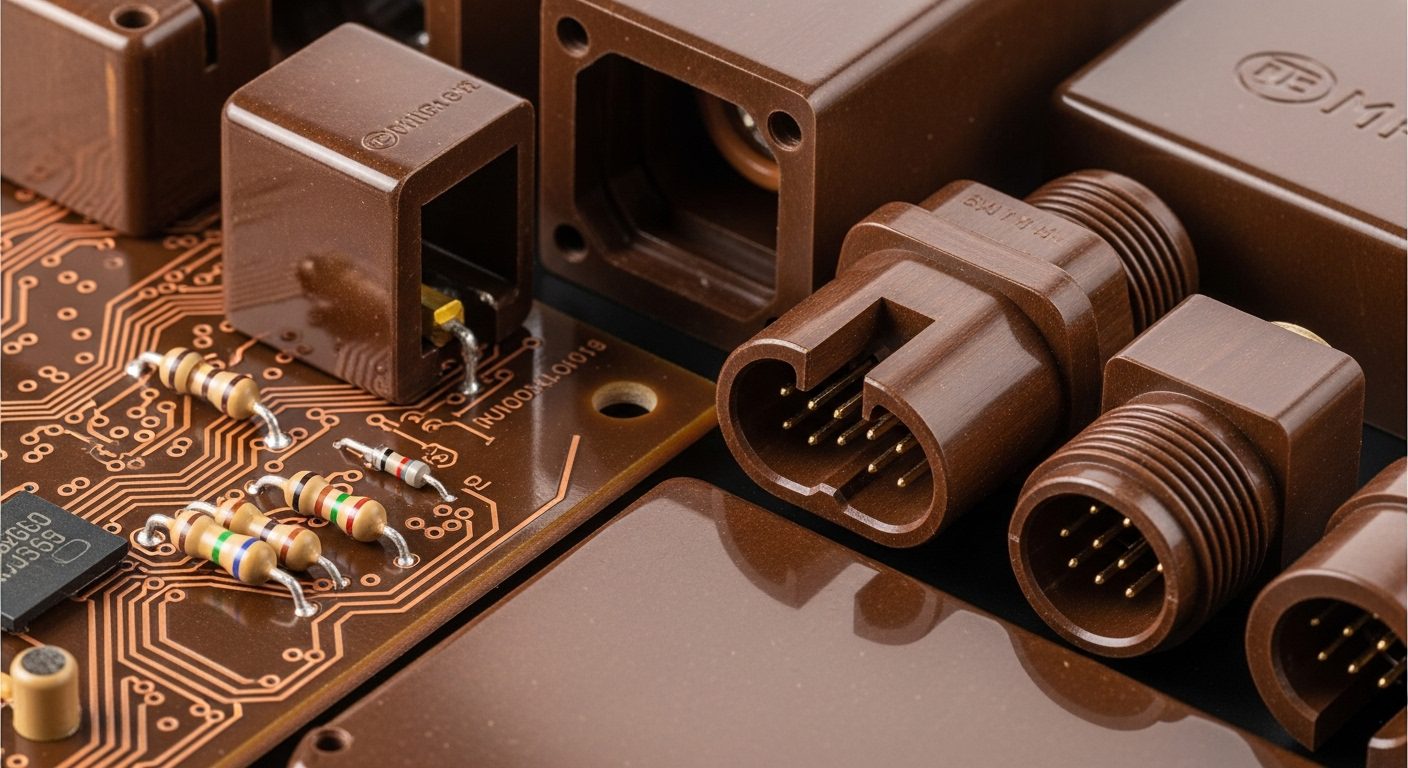

Electronics Industry

Electrical-grade phenolic compounds with excellent insulation properties for circuit boards, connectors, and housings. Superior arc resistance and flame retardancy for electronic applications.

Industrial Equipment

Heavy-duty phenolic compounds for industrial machinery, pumps, and processing equipment. Exceptional chemical resistance and mechanical strength for harsh industrial environments.

Construction & Building

Fire-resistant phenolic compounds for architectural panels, insulation systems, and structural components. Meeting building codes with superior flame retardancy and low smoke emission properties.

Chemical Processing

Chemically inert phenolic compounds for corrosive environments, laboratory equipment, and chemical processing systems. Outstanding resistance to acids, bases, and organic solvents.

Need Custom Phenolic Solutions? Let's Engineer Together

With 30+ years of phenolic molding expertise and 10 dedicated production lines, we create custom compounds tailored to your exact specifications and performance requirements.

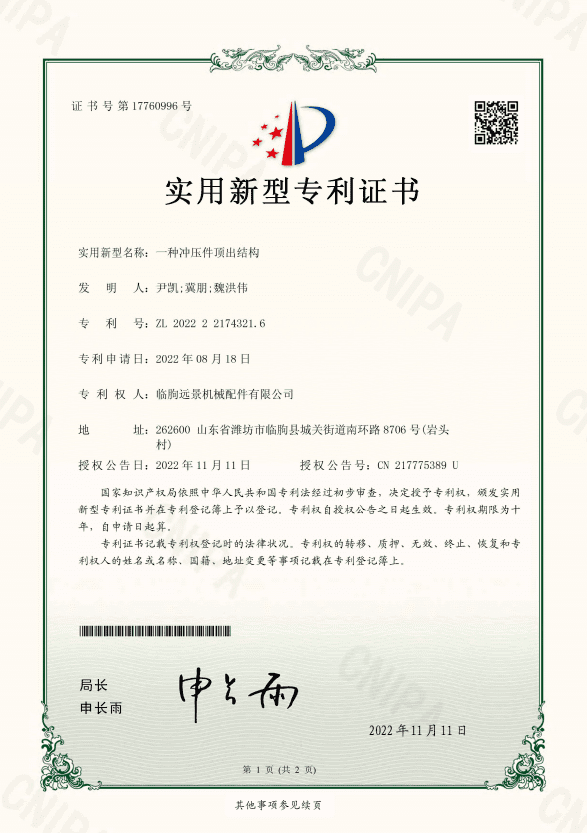

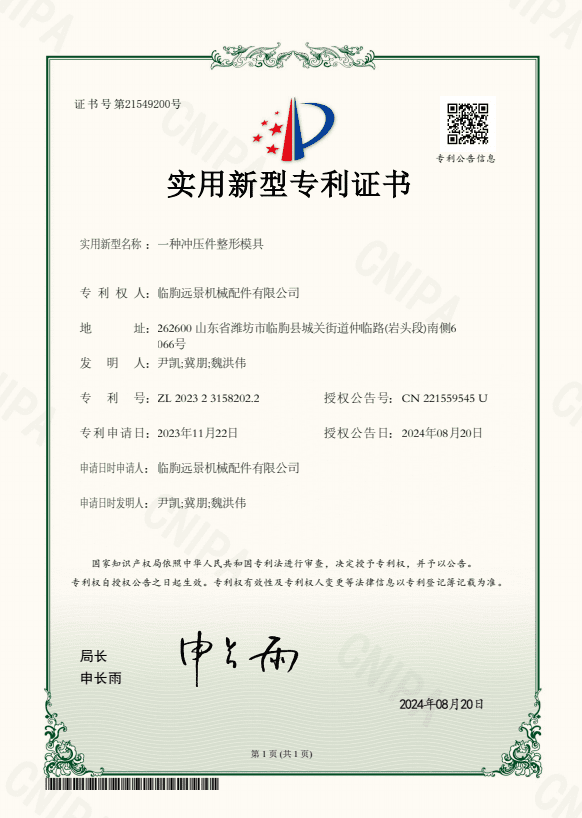

Quality System & Certifications

Over 30 years of excellence backed by international certifications and rigorous quality standards. Our commitment to quality ensures every product meets global manufacturing requirements.

ISO 9001 Certified

International quality management system certification ensuring consistent excellence

Rigorous Testing

Comprehensive quality control processes at every stage of production

Global Standards

Meeting international manufacturing standards for worldwide market compliance

What Our Clients Say

Hear from our satisfied customers across North America, Europe, Middle East, and Australia

"長年にわたる山東プライム社とのパートナーシップの中で、同社のPhenolic Molding Compoundの精密な成形性能と材料安定性は、当社の厳しい要求に常に応えてきました。 ISO認証のプロセス管理と迅速な対応力が、私たちのグローバル生産を強力に支えています"

"Die Präzision und Qualität der Phenolic Molding Compounds von Shandong Prime erfüllen die höchsten deutschen Industriestandards. Ihre modernen Produktionsanlagen gewährleisten eine gleichbleibende Materialperformance und zuverlässige Lieferketten für unsere anspruchsvollen Fertigungsprojekte."

"Shandong Prime has been our trusted supplier of Phenolic Molding Compounds for over eight years. Their material expertise and technical support have helped us enhance product performance and achieve consistent quality across every production run."

"Shandong Primes Phenolic Molding Compounds uppfyller våra stränga nordiska kvalitetskrav. Deras ISO-certifierade produktion och pålitliga leveranser har varit avgörande för våra industriella projekt inom högpresterande plastkomponenter."

"We rely on Shandong Prime’s Phenolic Molding Compounds for high-temperature and wear-resistant parts in our mining systems. Their materials deliver consistent mechanical strength and thermal stability — backed by prompt service and solid technical know-how."

"L’expertise technique de Shandong Prime dans la production de composés de moulage phénolique (Phenolic Molding Compounds) répond parfaitement aux exigences de l’industrie française. Leur capacité de production et leur contrôle qualité certifié ISO garantissent une flexibilité et une constance exemplaires pour nos applications sur mesure."

"Die Phenolic Molding Compounds von Shandong Prime erfüllen unsere höchsten Schweizer Qualitätsanforderungen. Ihre über 30-jährige Erfahrung und ISO-zertifizierte Produktion garantieren eine zuverlässige Partnerschaft für unsere präzisen Industrieanwendungen."

State-of-the-Art Manufacturing Facility

Our advanced Phenolic Molding Compound production line combines thermoset chemistry, automated molding systems, and stringent quality control to ensure high-performance industrial components.

Phenolic Molding Compound Frequently Asked Questions

Find answers to the most frequently asked questions about our phenolic molding compound products, specifications, applications, and ordering process.

Get Your Custom Quote Today

Join hundreds of satisfied clients worldwide. Share your requirements and receive a detailed quote within 24 hours.

Your Privacy is Protected

Confidential Information: All technical drawings, specifications, and project details are kept strictly confidential and never shared with third parties.

Secure Data Handling: Your contact information and files are stored securely and used only for project communication and quote preparation.

No Spam Guarantee: We respect your inbox. You'll only receive relevant project updates and our occasional industry insights newsletter (opt-out anytime).

ISO Compliance: Our data handling practices meet international ISO standards, ensuring your information is managed with the highest level of security.

"30+ years of trusted partnerships built on confidentiality and integrity"